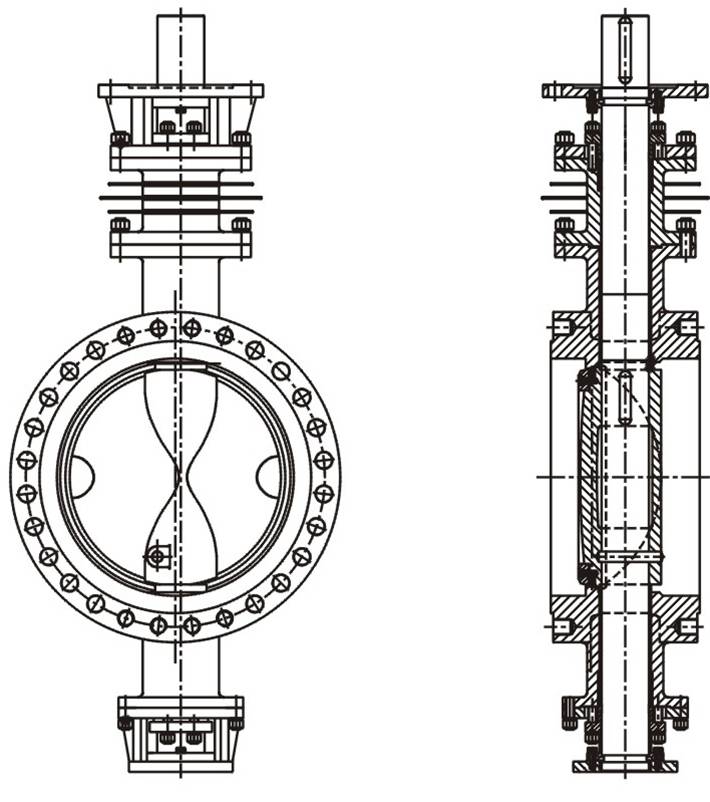

High temperature service triple offsets butterfly valve

|

Class 150Lb-600Lb End RF, BW Class Size Arrange Structure Triple Offsets Actuator Worm, Electrical, Pneumatic 150Lb 4”-60” Related standards 300Lb 4”-60” Design ASME B16.34 Test API 598 600Lb 4”-60” End B16.5/B16.25 Top flange ISO 5211 Medium: Water, Air, Oil, Gas, Steam, Special hot oil etc

|

>>Introduction:

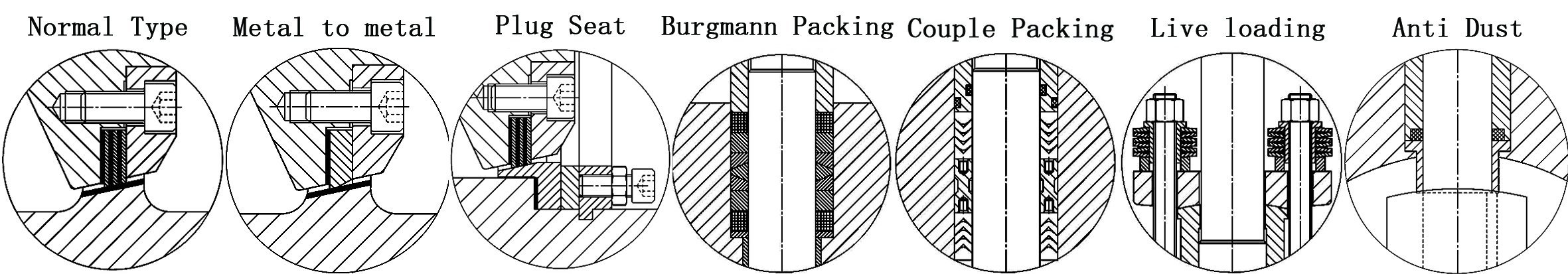

High temperature service butterfly valve structure is triple offsets, working temperature can be +595℃,+816℃。

As per high temperature service butterfly valve service requirement, we use complete different design theory, optimize design solution about different material extend rating in high temperature scope, and keep seal effort is well.

Valve body has to be passed RT test before into produce process, RT test is Class II as least; all the welding on the body has to be followed by ASME IX requirement, and be traced in files.

All valve parts in wet arrange will be in special heat treatment.

The extend stem length dimension is as per real working temperature condition, and target is pipe temperature can’t effect actuator’s working.

All high temperature’s testing & inspection is strict as per quality control procedure, so it’s delivery time is slow than normal triple offsets butterfly valve delivery days.

|

No. |

Part name | |||||

|

816℃ |

816℃ |

595℃ |

595℃ |

816℃ | ||

|

1 |

Body |

CF8 |

CF8M |

WC6 |

WC9 |

CK40 |

|

2 |

Disc |

CF8 |

CF8M |

WC6 |

WC9 |

CK40 |

|

3 |

Stem |

XM-19/310H/316H/304H | ||||

|

4 |

Seat |

Stellite welding | ||||

|

5 |

Seal Ring |

XM-19+Graphite/Ceramic fibre | ||||

|

6 |

Packing |

Graphite | ||||

All dimension is in our catalouge.

Catalouge download: http://www.cnvtrade.com/_d276407776.htm contact us for download password.